An Afternoon with Six Mile Bikes: Kootenay Born

Located a few minutes north of Nelson, British Columbia, Six Mile Bikes is a new framebuilder offering made-to-order bikes with a refreshingly personal approach inspired by a career as a ski guide. We stopped by the shop to get to know owner Kevin Armstrong, hear about the framebuilding course he took in Spain, and take a closer look at a handful of bikes he’s made…

PUBLISHED Aug 5, 2024

Kevin Armstrong of Six Mile Bikes describes getting into framebuilding as a “pandemic project that went wrong.” Up until recently, he was a firefighter in the summer and a ski guide in the winter but was looking to switch up his summer career. Kevin stumbled upon a framebuilding course through Escuela Técnica de la Bicicleta (ETB) in Madrid, Spain, and decided to sign up. He’s always had a passion for bikes, and ETB had the instructors and expertise to ignite something new inside him. He especially appreciated their unique brazing methods and thoughtful approach to framebuilding, which he now strives to achieve in his work. After building bikes for friends for a few years, Six Mile Bikes officially launched in May, and Kevin has been designing and building frames full-time since then.

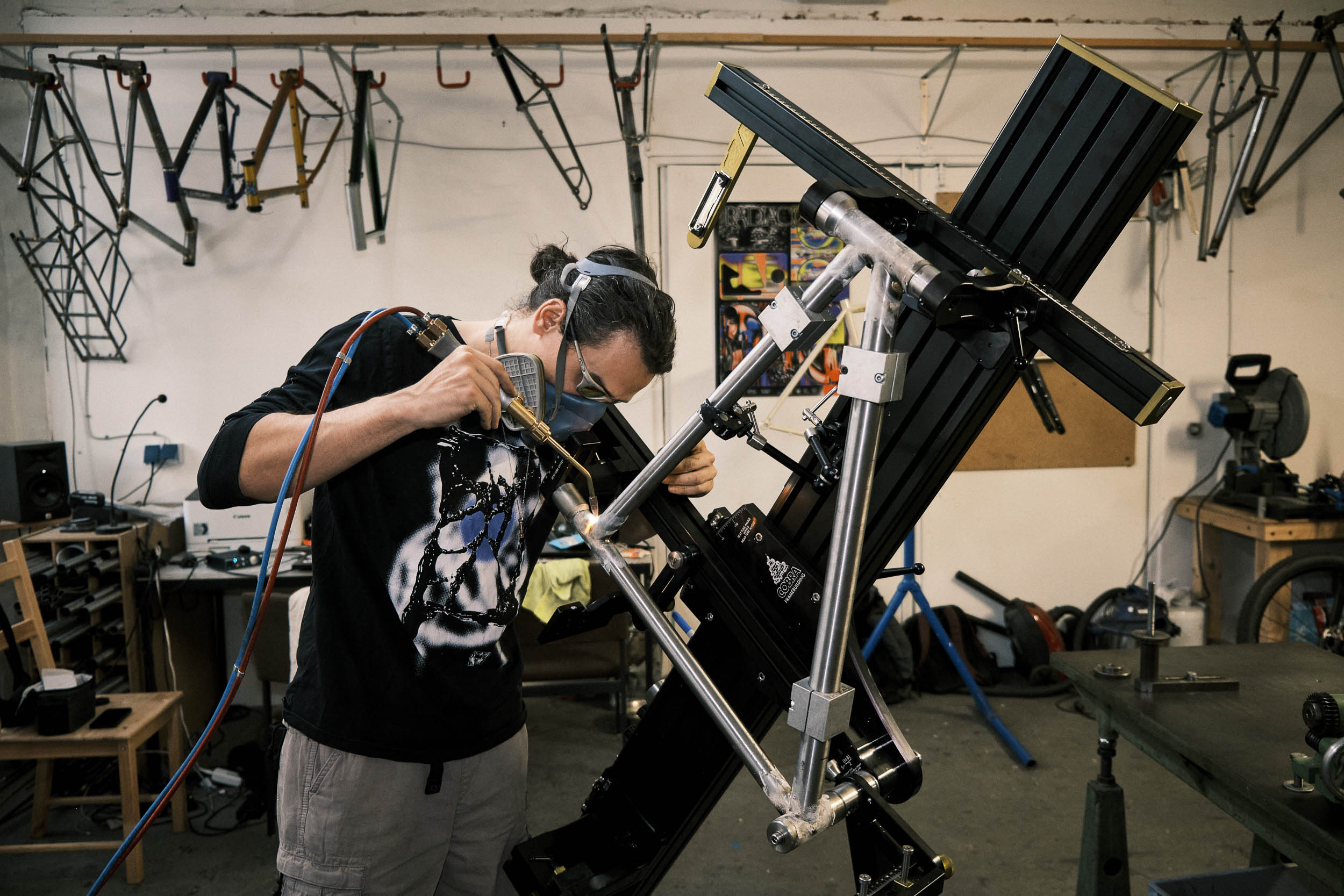

During the framebuilding course, Kevin also learned how to paint frames, and he recently set up his own paint booth at his shop after renting a space from an auto painter nearby. He’s really enjoyed the process of getting his space up and running. When I asked him if there was anything specific he learned in Spain that’s different from framebuilders in North America, he explained that the process and overall design doesn’t change, but he has been trying to emulate their clean, compact fillet, rather than filing down larger fillets. “I’m working on getting it to my instructors’ level. It’s not all there, but it’s coming along,” Kevin shared. “It just requires so much extra labor; though I can appreciate the aesthetic of doing so, it just doesn’t make sense to me. I would like to learn TIG welding because they’re quite similar, but I really enjoy the process of brazing. It’s not as hazardous, you’re not burning holes through your tubes, and I enjoy wicking the brass around.”

As Kevin walked me through the shop, he explained it was an unfinished woodshop when they moved in. There was janky wiring, uneven flooring, and not much of a roof. Kevin cleaned everything up, got his hands on some machines, and installed a woodstove to keep the space warm. The space had that intentional yet somewhat chaotic feel that comes with a well-used workshop, which is impressive considering Kevin has only been working out of the shop for two years. There was a run bike being made for his daughter currently in the jig, something he described as “the gnarliest run bike you’ve ever seen.” He has plans for a loud paint job and components that are probably overkill for a 9-month-old, but it was clear Kevin was very excited to get her riding. The fork is pleasantly short, as you can imagine, and the chainstays have a wild flare to accommodate a standard quick-release hub. The disc brake tabs were brazed into place while I was there, and Kevin explained he would likely have to cut out some of the chainstay to make room for the rotor. He laughed as he said he knew the bike would be left out in the rain, get rusty, and scratched up. Six Mile Bikes is planning to be down at the MADE handmade bike show in Portland, where he’ll have the run bike and a few other recent builds on display.

Most of Kevin’s customers have been local, within British Columbia and Alberta, and mostly from word of mouth and through friends. “In order to make this a viable business, I probably have to sell my frames for more than I’ve been selling them, and most likely from bigger city centers, so broadening my reach.” Kevin also has been tossing around the idea of making it customary for customers to pick their finished bike up in person. While he understands that’s not possible for everyone, if someone is making the drive out to pick up a bike, he figures they should at least get out for a ride, try the bike out, and get everything dialed in.

Nelson, and the West Kootenays in general, is the perfect backdrop for this type of service, as there is such a variety of terrain that’s easy to access right from the Six Mile Bikes workshop. Directly across the highway from Six Mile Bikes is an area known as the Nelson North Shore, which is packed full of steep singletrack, big slabs, and impressive woodwork. For gravel riding, the Duhamel Creek forest service road is just around the corner and serves as the kick-off point for a delightful overnight bikepacking route we’ll be sharing soon.

Kevin is currently working on a new bikepacking rig—think drop-bar, Cutthroat-esque, full-suspension bike called the Kootenay Adventure Bike (KAB). He’s designing it around drop bars because he likes the different hand positions they offer and prefers riding in the hoods on long rides, but there’s a good chance it could be set up with flat bars as well. He’s planning to make the axle-to-crown slightly longer to accommodate a suspension fork, likely a Fox 32, and it will use asymmetrical stays, 60mm travel in the rear and 100mm up front. The plan is to test the bike for a period of time, and if he’s happy with the ride and build quality, potentially explore the possibility of a small production run with custom sizing and paint. At that point, Kevin said he might have to consider expanding the company, which he doesn’t see as a bad thing.

Like many framebuilders, he’s experimenting with 3D-printed joints for the pivot points and swingarm, which use more of a lug-style joint rather than joining inside the tube like most frames. Kevin is excited about 3D printing, especially for projects like this that would have to be machined from aluminum or made of carbon. The printing process allows the parts to be made from sintered steel, meaning the steel powder is heated to very high temperatures, which results in a harder and stronger final product. The downside is that there is slight deformation in the parts when they cool down. In the plans, they are perfectly round, but they have to make clamps to hold the parts in a repeatable way so they can be machined to accept bearings, for example.

The far end of the shop is where Kevin stores raw materials and does the actual brazing. His jig is on wheels, so he can roll it outside onto a concrete pad to avoid welding inside. “The benefit of working from home is that I won’t get evicted if I don’t make rent, but there are are challenges to framebuilding on your own property.” With help from his dad, he’s expanding his outdoor workspace with a covered area for his grinder, sandblaster, and some other tools. A few hundred feet from the shop, past a garden, the property backs onto the Kootenay River, with West Arm Provincial Park looming above, just across the water.

Kevin studied at the University of Toronto and had plans to get into teaching before making the move out west. He was into rock climbing and skiing and eventually made the move to the Kootenays to be closer to that. Kevin initially approached cycling in a utilitarian way, commuting to work or cycle touring solo from Victoria to San Francisco. Today, he rides and enjoys it all; Nelson singletrack, road cycling, gravel riding, and bikepacking. As a kid, Kevin’s dad owned a musical instrument repair shop, where he worked throughout university. He spent his days sitting at a bench whittling away on very finicky instruments, and he also learned how to use a lathe and to appreciate working with his hands. He sees framebuilding as his way of coming back to that. With a six-year-old and a nine-month-old in the family now, Kevin is excited to spend more time with them during the summers. Seeing the idea for a framebuilding business shaping up feels like a big next step in his new chapter.

The Six Mile Bikes logo and headtube badge is a great horned owl. Kevin wanted a head tube badge that gave the bikes character, not just a letter or a simple symbol. He had always liked brands using animals as their badges and eventually landed on an animal of his own. Kevin explained, “Owls are also pretty amazing predators that are stealthy and lethal. In addition, we live on a beautiful delta that is home to an abundance of bird species, including owls, so it seems fitting to represent the area where the bikes are made.”

Five Six Mile Bikes

Svoboda Gnar Tail

Svoboda translates to “freedom” or “acting without restraint” in Russian. It is also the name of a local riding area just east of Nelson. The Svoboda Gnar Tail was made in collaboration with and for local ripper Jakob Salix. It is meant to go downhill, fast. Road gaps, jump lines, Nelson tech trails. “I’m excited to see this bike shred Nelson mountain bike trails. Jakob had total input on the geometry, and we collaborated on the lines, gussets, and paint. It was truly a pleasure to build this, and I love the way it turned out.” The paint color is called “Latte,” which Kevin says matches Jakob’s earth-toned and natural aesthetic.

Frame Specs

- Headtube Angle: 64.5°

- Seattube Angle: 75.5°

- Stack: 630mm

- Reach: 454mm

- Chainstays: 435mm

- BB Drop: 50mm

- Trail: 130mm

- Build Weight: TBD

Randognar Bikepacking/Gravel Bike

This Randognar was built for local former pro road cyclist Paul Kelly. It is designed for long road touring and bikepacking. Paul is an extremely strong rider, so the frame was designed with strength and stiffness in mind. There is clearance for 29 x 2.1” tires, and Paragon sliding rocker dropouts were used in case of a chain/derailleur break or if Paul wants to run an internally geared hub in the future. The bike was finished by Kevin using a custom-mixed silver/blue matrix urethane paint, and the end result is stunning.

Frame Specs

- Headtube Angle: 70.5°

- Seattube Angle: 73.5°

- Stack: 615mm

- Reach: 400mm

- Chainstays: 445mm

- BB Drop: 75mm

- Trail: 78mm

- Build Weight: 24lbs (10.8kg)

Sunsetter Bikepacking/Gravel Bike

The Sunsetter was made for Kevin’s friend Boyd Badiuk. It is a lightweight but capable gravel/ bikepacking frame that has some geometry similarities to a Salsa Cutthroat but with a longer headtube and a higher stack for extra comfort and frame bag space. Boyd went with a set of Spinergy GX Max gravel wheels, which are both lightweight and incredibly strong and also offer a plush ride thanks to their PBO fiber spokes. It has clearance for 29 x 2.1” tires, has a custom two-piece Field and Forest frame bag, and Kevin recently borrowed the bike from Boyd to participate in a White Grizzly gravel camp hosted by Svein Tuft. The flashy metallic green paint job looks even better in person.

Frame Specs

- Headtube Angle: 69°

- Seattube Angle: 74°

- Stack: 645mm

- Reach: 415mm

- Chainstays: 445mm

- BB Drop: 70mm

- Trail: 90mm

- Build Weight: 22.5lbs (10.2kg)

Duhamel Hardtail

The Duhamel is Kevin’s personal do-it-all hardtail mountain bike, painted in “Starburst Orange” with a matching fork. It’s designed to be slack, long, and light. According to Kevin, it climbs and descends well and is his go-to bike for just about everything in the Kootenays: bikepacking, singletrack, and cruising with the family.

Frame Specs

- Headtube Angle: 65.5°

- Seattube Angle: 75°

- Stack: 630mm

- Reach: 485mm

- Chainstays: 435mm

- BB Drop: 60mm

- Trail: 110mm

- Build Weight: 29lbs (13.1kg)

Jessamyn Road Bike

The Jessamyn is Kevin’s personal lightweight road bike. It features neo-retro aesthetics with rim brakes, some lugs, and classic lines. It’s made using a mix of Columbus Life and True Temper S3 tubing. It’s the bike he uses when commuting to town, taking long solo rides on winding mountain roads, and racing with the local road crew. Kevin explained this is not your do-it-all road bike. There are no rack or fender mounts, and the tire clearance is tiny. He’s fortunate to have other bikes that offer more utility when needed.

Frame Specs

- Headtube Angle: 72.5°

- Seattube Angle: 73.5°

- Stack: 565mm

- Reach: 390mm

- Chainstays: 405mm

- BB Drop: 70mm

- Trail: 60mm

- Build Weight: 16.2lbs (7.3kg)

Looking Forward

Kevin is really excited to grow the company. Despite being the new framebuilder on the block, feedback has been phenomenal, and he looks forward to optimizing and innovating. He also pointed out that some aspects of the bicycle work really well and appreciates the “if it ain’t broke, don’t fix it” mentality. “I really enjoy the paintwork; I find it is where the frame really comes alive. I’m looking forward to doing some finishes of polished steel and raw fillets. I’m excited for the KAB, and depending on its success, the work put into that frame should translate well into other full-suspension bikes.”

Kevin is incredibly personable and easy to talk to, which I imagine translates into a comfortable process for his customers. There’s no doubt that working as a backcountry ski guide has helped hone customer service skills, which now translate into his work as a framebuilder—specifically, providing an experience for customers. Something we talk about often is finding a framebuilder who you connect with, but I think there’s also something to be said for the reverse: ensuring that the relationship goes both ways. Our conversations quickly ventured off-topic, which in my mind is a telltale sign of a good chat. Kevin asks questions, understands the unique needs of bikepackers, and is eager to share his passion. In fact, during my visit, he made plans to run an intro to framebuilding course for my friend Harry (who lives in Nelson) and is considering offering a few weeks of courses each summer. He has the space, and his proximity to fantastic local riding and the lake makes for a pretty attractive venue. Post-framebuilding dips in the Kootenay River? Sign me up.

I’m excited to follow along as Six Mile Bikes evolves and to see what types of bikes Kevin makes this summer. If you’re bikepacking in the area (stay tuned for some new routes out of Nelson) and want to check out Kevin’s shop, he’s open to visitors. Just shoot him a message or email to line something up. He will also be at the MADE handmade bike show in Portland later this month, so make sure to stop by his booth to check out the bikes in person if you’re in the area. Thanks for having us, Kevin!

See more from Six Mile Bikes at SixMileBikes.com and on Instagram.

Further Reading

Make sure to dig into these related articles for more info...

Please keep the conversation civil, constructive, and inclusive, or your comment will be removed.