Inside Outer Shell: Unity, Duality, and Spreadsheets

Founded in 2015 by Kyle Ng, Outer Shell prides itself on function-forward bag designs, minimalist style, and products that encourage customers to develop a deeper connection with their environment. We stopped by their San Francisco workshop to learn more about the Outer Shell origin story, meet the small team, and take a quick look at three staff bikes. Find it all here…

PUBLISHED Apr 18, 2024

On a recent road trip between southern California and British Columbia, I realized I’d be passing by Outer Shell’s headquarters in San Francisco. This got me thinking about how little I knew about the brand, its history, and the people behind it. For one reason or another, there’s not much information about Outer Shell’s story online, so I jumped at the opportunity to stop by their shop to learn and share more about their work.

Outer Shell is tucked between a skate park and Highway 101 in San Francisco’s Potrero Hill neighborhood. It’s a semi-industrial area with a big metal gate to keep the curious out, a corrugated metal building facing the street, and a compound-like aesthetic that’s home to a handful of other small businesses, including artist/designer Chris McNally, whose work you’ll find pepper throughout the site. Aside from the collection of potted succulents and McNally’s trendy Volkswagen van out front, there aren’t many discerning clues as to what lies inside. It was raining when I arrived, which gave the buildings a slightly ominous feeling. I didn’t have a code for the gate and couldn’t get a hold of anyone inside, but I snuck in after a car entered—Operation Outer Shell was underway.

Outer Shell’s shop is just as discreet as the other businesses hidden behind the unassuming metal walls, given up by only a hand-written “Outer Shell” on the door. I caught them just before the spring rush, so the space was packed full of completed bags ready to be listed for sale. Every free cabinet and shelf in sight was stacked with rack bags, basket bags, and the rest of their product line. Any leftover space was filled with various sewing machines, huge rolls of fabric, hardware, and all the other bits and pieces you’d expect to see in a bag maker’s workshop.

The bulk of their inventory, shipping department, office area, and a makeshift in-house photo studio are at the far end of the room. Outer Shell founder Kyle Ng chuckled as he showed me this area, explaining how “the photo studio and office back into each other, so you can’t use both at the same time.” Similar to how the seemingly chaotic garage organization can only be understood by its owner, Outer Shell is a meticulously designed machine with every last detail accounted for. In fact, co-owner Jim Santos explained that the shop’s floor plan was laid up in CAD to prioritize efficiency and productivity. The gaps between the various workstations are sized to allow their rolling carts to fit through, and each sewing station faces the office area and has a dedicated entrance/exit to create a sense of flow.

Wave-Particle Duality & The Beginning

Precisely positioned sewing machines and the flow of intentionally designed workstations have more to do with Outer Shell than creating a productive shop. The name Outer Shell, or valence shell, refers to the outermost layer of an atom. Some electrons in this layer can move between atoms, commonly known as electrical current. While searching for a name for his bag business in The Last Book Store in downtown LA, Kyle found The Tao of Physics by Fritjof Capra, which explored the correlation between Buddhist ideologies and modern physics.

Inside was a section on wave-particle duality, “with an illustration of waves moving in the ocean and how the particulates just move in circles, but the wave can travel far even though none of the actual material or water is moving. It’s just the energy passing through it,” Kyle explained. This illustration inspired the original Outer Shell logo. Although Kyle took a lot of math and physics classes in community college, which has helped tremendously with bag making, he said he was likely drawn to this because he was probably stoned out of his mind and was thinking, “Woahhh, far out!”

The name Outer Shell builds on the interconnectedness of everything, enjoying the experience and feeling in tune with the environment. Kyle said he likes feeling immersed in nature. He cares less about stats and miles and more about helping people experience those connections. This approach also influences how they make their bags, the aesthetic, warranty and repair policies, and sustainability practices. They put their money where their mouth is by designing products that are durable and repairable, source materials locally when possible, are Climate Neutral certified, and have been a member of 1% For The Planet since 2020.

I can’t help but see a correlation between the energy of an ocean wave traveling vast distances and Kyle’s journey to building Outer Shell into what it is today, although perhaps not as smooth as the wave-particle duality diagram. Kyle grew up in LA and described himself as a “shitty kid” who was prone to getting kicked out of school and arrested, but he insists this rebellious side was important when starting his own business. Bikes weren’t an important part of his youth, but he returned to them in his early teens when bikes “weren’t just for getting around and started being cool.”

Around this time, he was getting into the punk scene, which led to joining Critical Mass rides, which were very political because LA is such a vehicle-oriented city. “It was tall bikes and studded vests. That was the vibe, and that’s how I got into biking.” This was when he started sewing, mostly super tight pants because they were hard to find back then. “Even women’s jeans weren’t that tight,” Kyle explained. The pants were hand-sewn, and all the threads would bust out at the seams, which was part of the style. People started asking where he got them.

Kyle expanded his circle and joined more riding groups, including Midnight Riders in LA, which was much more sporty and less political. One of his first bikes was a Cannondale CAAD 3 hybrid, but fixies were all the rage, so he picked up a Univega from the Bike Kitchen, a non-profit bicycle repair shop and put a bunch of red loctite on a cog on the freewheel to make it one. Kyle describes how being able to ride a bike from East LA to Hollywood through downtown LA was empowering when most people don’t even know it’s possible. When he was 17, Kyle convinced his parents to let him move to San Francisco with a bunch of friends. This was his first time traveling away from home without his parents. They went and saw the first MASH movie premiere, and Kyle was sold on the culture surrounding it. “It was a bunch of grimy-looking bike kids doing wheelies on 16th Street. I was like, this is the coolest place ever! Everyone was smoking weed and cigarettes indoors, and I was like, this is the Wild West out here!”

Bedroom Workshops and Goth Hackers

Kyle didn’t grow up camping as a kid, so he found backpacking in his late teens and got into gear that way. He was riding further and wanted to combine biking with hiking trips to access new terrain. One idea he played with was two panniers that zipped together to form a backpack, but it was overly complicated and didn’t pan out. On one test ride, one of the pannier hooks got sucked into Kyle’s rear wheel, snapped the bag’s frame, and sent him over the bars.

As rides got longer and longer, he began making bike bags to carry ride essentials and other gear. He made his first bag in 2014 when he was about 24 years old, and at that time, everything was still hand-stitched, including full pannier sets. A pivotal moment for Kyle was when the Prolly is Not Probably blog shared his tiny saddle bag, and he received 100 orders in one night. “I guess I had no limit on my Etsy page at the time. I would normally make one if someone bought one, but I had to all of a sudden make 100. I stayed up super late for multiple days to make them all.” The mini saddlebag can still be found in their product line today. During this spike in demand, Kyle was still working as a bike mechanic but wondered if he could start a business so he “didn’t have to listen to anyone,” as he puts it.

Outer Shell officially launched in Kyle’s bedroom, which had just enough space for a bed, a sewing machine, and his material piled around it. He lives in the same place today, but it’s three times bigger now because all his roommates have left. In 2017, he moved his shop into a DIY community maker space called Noise Bridge. There were hackers messing around with computers, a wood shop, and a metal shop. Kyle started a sewing area that was open to the public—a hitch Kyle felt was worthwhile for a free space.

“I don’t really know what they did, but there were a bunch of cool goth hacker nerds there, doing I don’t know what on their computers, but it looked wacky. They were into Julian Assange and stuff like that. I started a sewing class there, which sounds super righteous, but it’s just because people kept on fucking my shit up, and it allowed me to supervise people.”

Jim, Xin, and Alex

Jim joined Outer Shell toward the end of 2018. He was making his own bags under the Fog City brand, but “we were competing, and I was losing,” as he puts it. Like Kyle, MASH, Macaframa, and the fixie scene got him back into bikes. He connected with the freedom bicycles offered when moving around the city, as opposed to motorcycles, which he also rode. He worked in the corporate tech world for seven years straight out of college but eventually moved to San Francisco to tap into his creative side. Jim said he was obsessed with taking things apart and putting them back together as a kid. He’d unfold cardboard boxes and see if he could remake them—a skill that turns out to be super helpful for softgoods design, going from 2D to 3D.

Jim and Kyle met through San Francisco Fixed and fixie bike forums and were members of the San Francisco Coffee Outside chapter. In 2017, before he joined Outer Shell, Jim pitched the idea of joining forces, but Kyle wasn’t sold on the idea or how they’d form a working partnership. Neither was making any money then, which was also a problem. Just as Jim was about to return to a corporate job, Kyle asked if he wanted to revisit a partnership. Jim also had a bartack machine in his garage that Kyle had used on occasion, so the idea of joining forces started to make sense. They drafted an agreement, slowly merged their product lines, and have been co-owners ever since. Jim’s background in economics and business operations and Kyle’s in mechanical engineering, CAD, and product design are complementary skill sets that work well. “I feel like if Jim wasn’t around, I might have just tanked it.”

Xin came on while Kyle was still working out of Noise Bridge. She comes from decades in the textile manufacturing industry that used to be big in San Francisco and is still very much connected to those people. Kyle purchased some machines from a closing factory, made friends with the owner, and met Xin through them. She is the head seamstress and manages the sewing team—two of her friends. One works from home, and the third sewer works on-call/part-time.

Xin’s background is in sample making, and she’s excellent at using a sample to make a final product. She irons out the manufacturing details that either make or break a product and keeps Kyle and Jim in check from a manufacturing standpoint, sometimes sending them back to the drawing board. While the features of any particular product stay the same, figuring out how it’s made can change in such a big way.

They worked out of Noise Bridge for two years before moving to their current location, which used to be Chris McNally’s screen printing shop. Before they moved in, a giant conveyor belt dryer for prints and several screen printing presses filled the space. They originally shared the shop with someone else but slowly took over and are now pretty much maxed out.

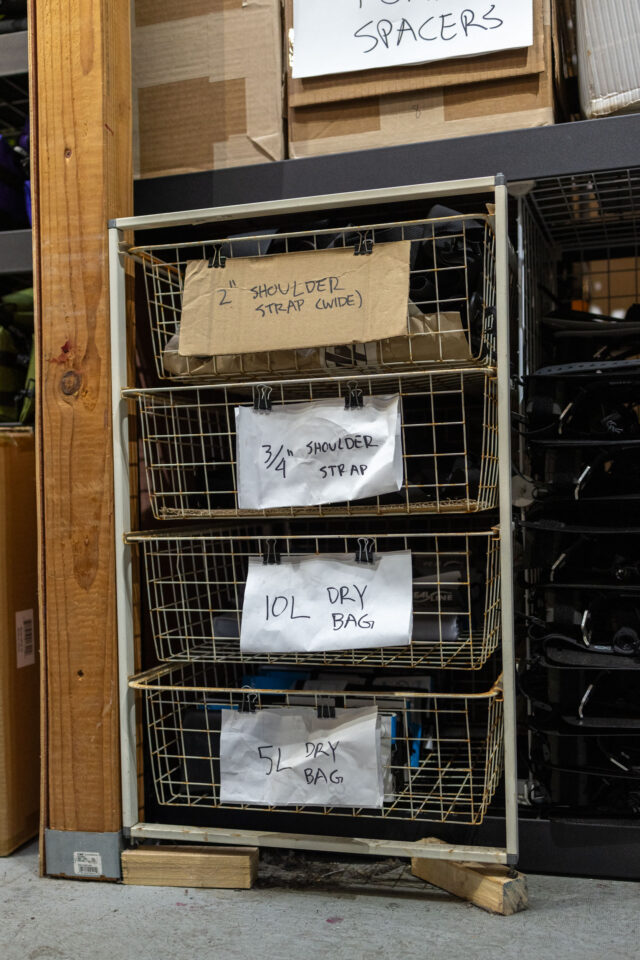

Alex Steadman, Outer Shell’s newest employee, started a month before my visit. He moved to the Bay area in 2018, met Kyle and Jim through coffee outside, and has always worked in the bike industry—something Kyle sees as an asset. Alex oversees order fulfillment, cutting strip parts (velcro and webbing), and Outer Shell’s social media. Oh, and he’s excellent at wheelies.

How It’s Made

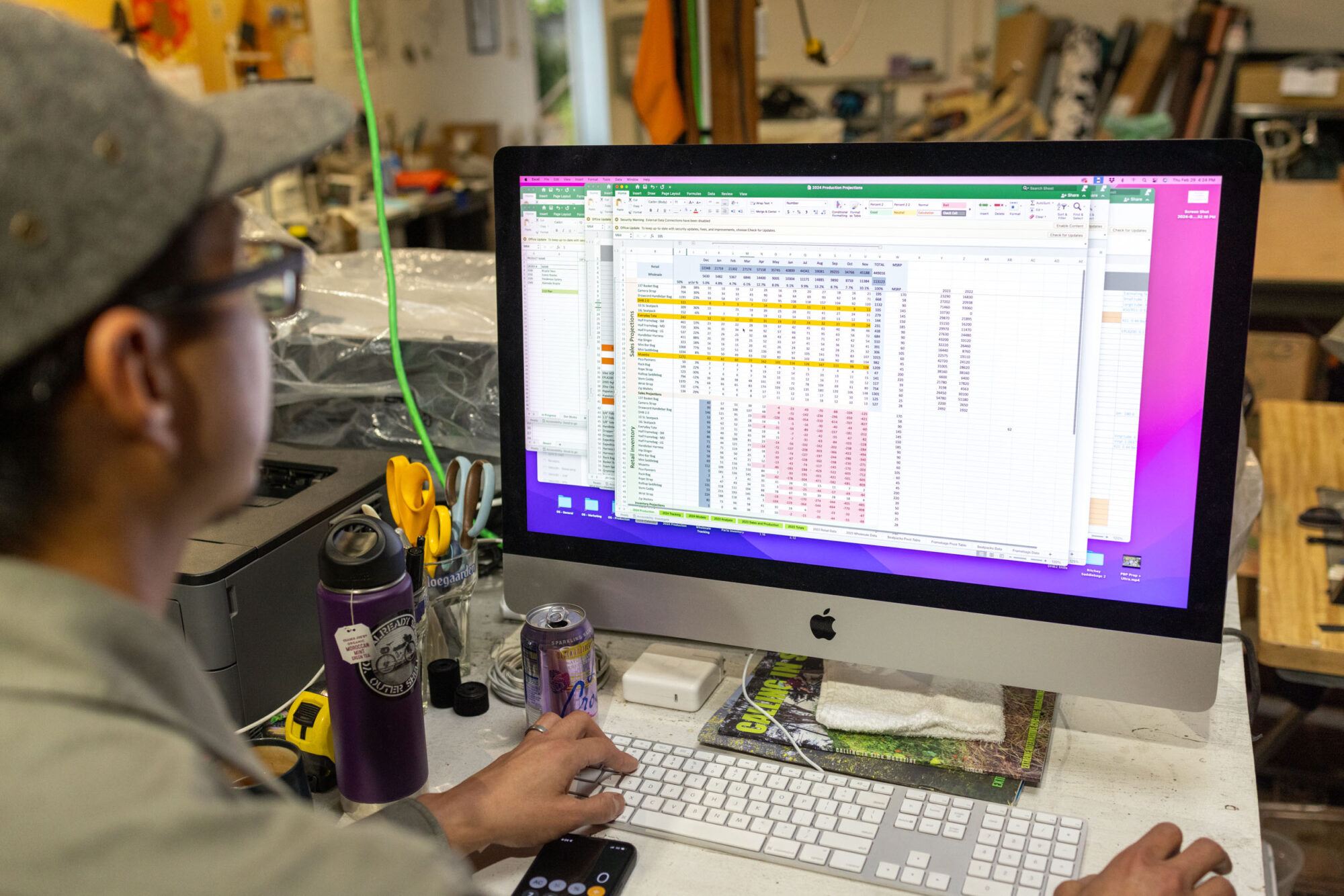

Before any material is cut or fabric is sewn, a spreadsheet determines what and when all Outer Shell bags are made. Everything is tracked using spreadsheets, including how many components or materials they’ll consume, when they need to restock, when to order, what they’ll make, and projections for the future. Jim’s corporate background involved a lot of the same work, and he enjoys it. He gave me a rundown of how their various spreadsheets work and the interconnectedness of everything, including consistent hours and paychecks for the sewing team. “We have tons of spreadsheets,” Kyle explained, “Without them, it would be a mess. We’d be making too much of some stuff and running out of other stuff all at once. It’s like overpacking and underpacking at the same time. Running out of components means halting production, and our team relies on steady work to get paid.”

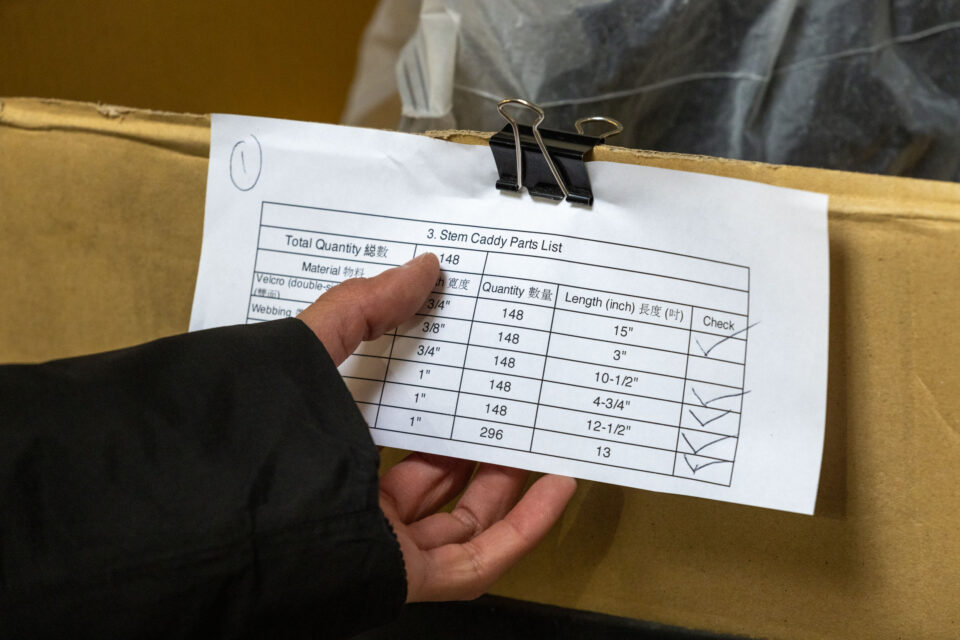

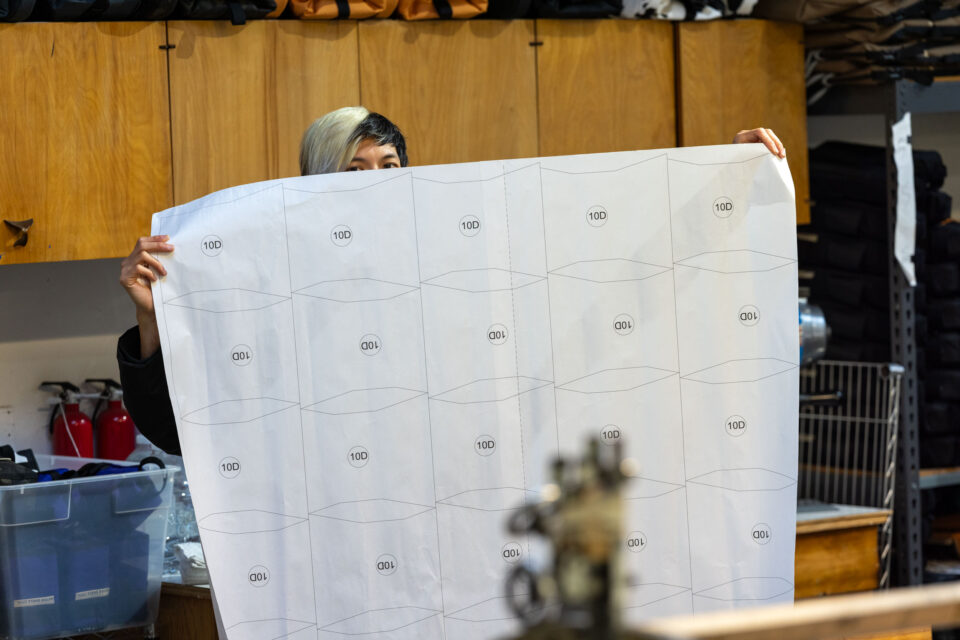

Each bag has a numerical identifier, and each fabric panel has a corresponding letter. For example, the parts of a #4 seat pack would be 4A, 4B, 4C, and so on. The patterns are laid out on a stack of fabric and cut out all at once using a satisfyingly vintage-looking Blue Streak fabric cutter. Strip fabrics, such as webbing and Velcro, are all sized and cut automatically using a strip cutter machine.

From there, Xin receives all the production receipts and delegates the next steps to the sewing team. They start with simple straight stitches and bartacks, or flat sewing, and then move on to making a 3D product. There are two flat sewing stations, a trim station dedicated to putting the seam edging found on all of their bags, and two cylinder arm machines for sewing hard-to-reach places. The final step is assembling straps, hardware, and buckles before the finished product is added back into the spreadsheet before being put on the shelf.

Their mini rando handlebar bag was one of the products that helped kick things off. It uses a rando bag design but doesn’t require a rack, and they’ve been working on reviving the design. One approach is using stick tech, where acrylic rods are sewn into the bag to act as stiffeners—holding the bag’s shape, supporting stretchy pockets, and ensuring the bag doesn’t collapse on itself. They used this design with their new Rando UL Drawcord Handlebar Bag and are planning to merge it over to the standard bag lineup soon.

They source all of their fabrics from X-Pac and Challenge Sailcloth, both based in Connecticut. Their stunning marigold X-Pac is a custom color they helped design but isn’t exclusive to Outer Shell. Kyle provided color swatches to X-Pac and they did a lab dip to find the exact chemistry to make the specific color they wanted. Their graphite and brown Cordura-style fabrics are also custom-made for them. Their cow print and floral teal fabrics have become signature prints, and both use dye sublimation that doesn’t use water in the printing process since the fabrics themselves are water-resistant. A lot of time went into getting their cow print just right, and they still have a huge fabric swatch with six options the fabric company sent them to proof. The fabrics they use are made in China, but most of the factories using these fabrics are also located in China, reducing the supply chain substantially. Otherwise, hardware and some components are sourced within the USA when possible.

Everything in the shop is written in Chinese and translated to English because all sewers communicate in Chinese. In total, the team currently consists of 2.5 sewers, Kyle and Jim working full-time, Alex three days a week, and a fabric cutter 8 hours a week. They’ve also been working with an ad agency to help create content and spread the good word. They’ve outgrown their current space and have been chatting about expanding into another unit nearby, but having everything in one room has been helpful. For example, instead of running over to an inventory building, they can immediately check the inventory and confirm the computer shows the same thing.

Becoming a Boss

Kyle’s transition from a defiant kid to owning a reputable bag-making business with several employees isn’t entirely unheard of, but I found it interesting nonetheless. I asked Kyle what he thought about being a boss, and here’s what he had to say, “Telling people what to do is kinda weird. I guess I’m a boss. It’s mostly a joke when I say that. I think I’m still learning how to do that. I guess I’m more responsible now, but part of that is me being obsessive. I have an addictive personality where I obsess over something. It has less to do with being responsible and more with me being obsessed with making something perfect.” Kyle quickly acknowledged that he’s had many mentors over the years, including Garrett from Strawfoot, a friend who owns a high-end clothing company in Brooklyn, and Yanko in LA. Other makers constantly inspire him, and he loves checking out their shops in person when possible.

When I asked Kyle and Jim about the future of Outer Shell, there was no mention of expanding production or taking over the world. Kyle simply explained that he likes making stuff and he “wants to keep doing that,” but he wasn’t blind to the fact that Jim has a family to support. Jim jumped in and explained, “Those goals are not in conflict. We make money because this guy enjoys designing bags.”

Coming up with the ideas isn’t hard for Kyle and Jim, but making them repeatedly in a business-viable way is the real challenge—which is why they are so grateful for their team. Kyle emphasized the importance of keeping his products accessible, which means not ultra-proprietary or expensive. Moving forward, Kyle has been thinking about using 3M dual-lock to make clicking foam blocks, adding stick-tech into other bags, and has plans to release a big top-opening handlebar bag that doesn’t flop or sag and doesn’t require a wood dowel “like you’re from the 1800s.” He’s also been thinking about a handlebar bag support that doubles as an accessory bar for devices after running into Lael Wilcox last year using some sort of handlebar booster bar filled with lights and computers.

Kyle’s Rivendell Bleriot

Kyle found this stunning Rivendell Blériot under a tarp in the previous owner’s backyard. He picked it up for cheap and got it up and running using some parts he had kicking around. It features a custom-painted Rat King T-Rack (now made by Tumbleweed) in the back, a Pass and Stow front rack with an Outer Shell Rack Bag on top, and a grocery-bag-protected Berthoud Aspin saddle. A SON dynamo light, Panaracer Gravel Kings, and some timeless hammered fenders get Kyle where he needs to go in the city.

Jim’s Hunter Hardtail

The Woodrat 29er is Jim’s second Hunter Cycles. It was part of a batch of five Woodrats that Rick Hunter started in 2019, and this particular frame was originally intended for someone else. They pulled out, and after some hemming and hawing, Jim decided to add another “if you could only keep one” bike to his collection. The build features a Hunter Smooth Move Low Rise handlebar, PNW Components Loam dropper post, and WTB rubber. It’s kitted out with a complete set of Outer Shell’s new Ultra bags, including a Half Frame Bag, Mini Bar Bag, and a Mini Saddle Bag.

Alex’s Jamis Nova

Alex picked up his 2007 Jamis Nova last year as a lockable road bike for the city. After only ever riding mountain bikes, he decided it was time to get full fenders to make it through another rainy winter season and found the Jamis for cheap on Craigslist. The original owner replaced the stock carbon fork with a steel Soma fork, but everything else is Alex’s.

“I’m not the heaviest guy, and I like a smooth riding frame, so the flexy Reynolds 631 with some plump tires is great. The original owner had replaced the stock carbon fork with a steel Soma fork, but everything else is mine. I’ve been committed to 1×11, Toupe saddle, flat bars, and platform pedals for years, so I had most of the parts around. Hacked-up SKS Bluemels Style fenders wrap around the 38/42mm tires that measure a few millimeters skinnier since they’re on some truly scary Mavics. Twenty spokes front and rear and all the nipples are seized to the bladed spokes. There was a hop in the back, so I had to cut out and replace a couple of spokes to get it straight enough. Of course, there’s a basket that I can easily take off to turn it into “road mode” so I can get dropped by everyone. Finally, I put some cheap 155mm kids BMX cranks on to test the shorter length without breaking the bank. So far so good!”

Wrap Up

If there are two things I took away from my visit with Outer Shell, it’s that they run a tight ship, and they do so to support their team and the environment around them. There is so much intention behind every decision they make, and no secret master plan or puppeteer hiding in the shadows. It’s been Kyle on the front stage since the early days of working next to his bed, and even though Outer Shell has grown as a business, he’s been right there the whole time. He works closely with everyone on the team, and seeing him interact with Jim, Alex, and Xin, it’s clear that there’s a high level of trust and respect in their small shop—despite a healthy amount of goofing around. Take a closer look at their bags at OuterShell.com.

Further Reading

Make sure to dig into these related articles for more info...

Please keep the conversation civil, constructive, and inclusive, or your comment will be removed.